- |

-

English

- |

For this double layer metal sheets roofing machine, you can choose tilespan and ribtype, also can choose IBR and wave type,by this design, can save space and cost, but kindly note one thing: both layers cannot run at same time.

The machine adopt automatic control and Manual control two types, easy operate.

The machine's products are steel metal roofing and wall sheet .

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

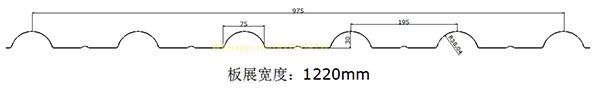

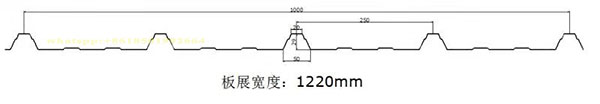

1), Materials width: 1220mm

2), Sheet Materials thickness: 0.3-0.7mm

3), Effective Width: Based on sheet drawing

Usage: It is used to support the steel coil and uncoil it in a turnable way.

The steel coil is uncoiled by hand. Loading capacity:5T,Inner diameter: 500-508mm

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Machine Material of rollers: 45# steel,roller surfaces polishing, hard plating.

The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped

Hydraulic oil into the hydraulic oil tank,the pump drive the cutter machine to begin the cutting job.the target piece`s length is adjustable and digit of it can be djusted.Computed mode has two modes: automatic and manual one. The system is easy to operate and use PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: ;Cr12,quenching treatment

Output Table: It adopts welded steel and supported roller to transmit the products, which is used to collect the finished products.