1), 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine Raw Material

Feeding width: Up Layer 1200mm, down layer 1200

Effective width: Up layer 1035mm, down layer 1040mm

Materials thickness : 0.3-0.8mm

2), Main 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine

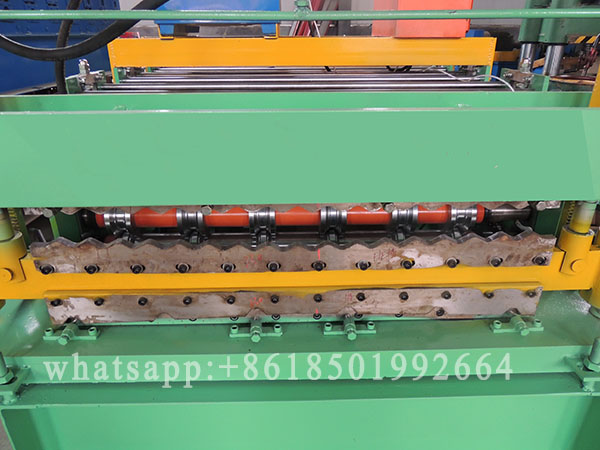

Roller material: 45# steel plated with chrome

Diameter of shaft: 75mm

Roller station steps: Up layer 15 Stations; down layer 16 stations

3), Main 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine Configuration

Main motor power: 5.5KW

Hydraulic station power: 4KW

Control system : Full Automatic Control And Manual Control

PLC brand; Taiwan delta

4) Working Flow of 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine:

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

5) 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine Profile:

6) Main 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine:

7) 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine Cutter:

8) UCT Model Wall Plate Of 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine:

9) Feeding Device Of 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine:

10)Pump station and PLC control box of 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine:

11) Manual Control 5 Tons Decoiler of 1035 Metcoppo Step Tile Roofing Sheet And1040 Metral Longspan Roof Sheets Double Layer Roll Machine: