5 Peaks Industrial Roofing PPGL Sheets Roll Forming Machine's product panel has been used extensively by the construction industry throughout the World for nearly two centuries. Because of its excellent corrosion resistances, it has become the preferred material for a wide range of construction uses, particularly roofing and walling

1, Working Flow of 5 Peaks Industrial Roofing PPGL Sheets Roll Forming Machine:

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

2, Technical dates of 5 Peaks Industrial Roofing PPGL Sheets Roll Forming Machine:

Suitable for materials thickness: 0.3-0.8mm

Shaft materials: 45# Steel

Shaft diameter: 75mm

Motor driving, Gear chain transmission, 18 steps

Main motor is 4KW

Forming speed: 8-15m/min

3, Rollers manufactured from high quality 45# Steel, CNC lathers, heat treatment

With black treatment or hard-chrome coating for options

With feeding material guide, body frame made from 300 H steel or 350 H steel welcidng

4, 5 Peaks Industrial Roofing PPGL Sheets Roll Forming Machine Cutter:

Made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 20mm steel plate by welding

Hydraulic motor: 4KW

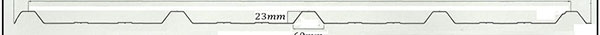

5, Main Profile ( Can customize the profile based on detailed drawing):