Quickly Change Automatic Control Z Purlin Roll Forming Machine Z100-Z300 in all metal or mixed building roof systems, purlin members are frequently constructed from cold-formed steel Z sections. Purlin roll forming machine is special designed for its production.

1, Quickly Change Automatic Control Z Purlin Roll Forming Machine Z100-Z300 Working Process:

Decoiler→Flating→Feeding punching→Forming→Cut to length→Collection

2, Quickly Change Automatic Control Z Purlin Roll Forming Machine Z100-Z300 Techical description:

1)Decoiler

Decoiler Type: manual decoiler

Weight capacity of decoiler : 5.0T

Inner diameter: 350-550mm

Outer diameter: 1200mm

2)Feeding and Leveling Device

It used for making the material flat before feeding into the roll forming machine.

Roller:7rollers, 4up,5down

3)Rolling Forming System

It can change different sizes automaticly and different size you just input data in PLC.

Main motor power: 18.5kw

Speed of forming: 8-12m/min

Material of roller : Gcr15steel polished and coated with chrome HRC55-60°

Roller: 15 groups rollers

Material of main shaft : High grade No.45 steel after treatment

Diameter of main shaft: ø80mm

Driven: 1 chain

4) Hydraulic Punching and Cutting

punching Type: Hydraulic Punching

Punching material: Cr12 steel after treatment

Punching die: Cr12 steel after treament

Cutting material: Cr12 steel after treatment

Hydraulic motor power: 5.5kw

5)Control system

Type: PLC Frequency Control System with touch screen

PLC Brand: Japan Panasonic

Encoder Brand: Omron

Length Error: ±2mm

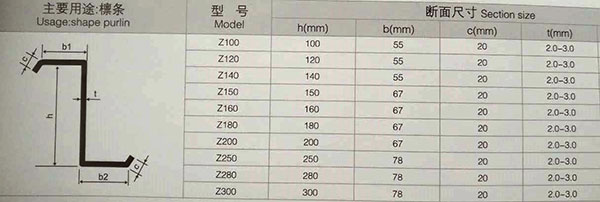

3, Quickly Change Automatic Control Z Purlin Roll Forming Machine Z100-Z300 Profile Size:

4, Quickly Change Automatic Control Z Purlin Roll Forming Machine Z100-Z300 Profile:

5, Quickly Change Automatic Control Z Purlin Roll Forming Machine Z100-Z300 :