Galvanised Steel Roofing CEE C Purlin Roll Forming Production Line For Constructions

The finished Steel C purlins are suitable for all constructions in which the spans are simply supported.Typical applications are building, roof, wall structure.

1, Main Parameters of Galvanised Steel Roofing CEE C Purlin Roll Forming Production Line For Constructions:

1), Suitable Raw Material: Galvanized Steel Coils, Strips Rolls

2), Width of Raw Material: Based on the design

3), Thickness of Raw Material: 2-3mm

4), Rolling Stations of Roll Former: 13-15 rows

5), Rollers Material: Gr15

6), Driving Motor Power: 15KW

7), Hydraulic Cutting and Punching Motor: 5.5KW

8), Production Line Speed: 8-25m/min

9), Diameter of Rollers Shaft: Φ85mm

10), Cutting Method: Hydraulic Post-cutting

11), Cutting Blades Material: Cr12

12), Cutting Tolerance: ±1.5mm

13), Electric Control System: Mitsubishi PLC, inverter and touching screen

14), Main Machine Weight: About 8.5 tons

2, Main Components of Galvanised Steel Roofing CEE C Purlin Roll Forming Production Line For Constructions:

1), Manual or Electric Decoiler........................... 1 set

2), Direction Guilder................................................1 set

3), Rollers Leveling Device....................................1 set

4), Holes Punching Deivce (optional)................1 set

5), Rollformer Machine...........................................1 set

6), Automatic Hydraulic Cutter.............................1 set

7), Mitsubishi PLC Controller.................................1 set

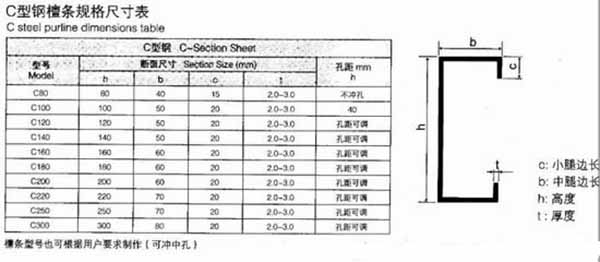

3, Galvanised Steel Roofing CEE C Purlin Drawing Size:

4, Galvanised Steel Roofing CEE C Purlin Roll Forming Production Line Products:

5, Galvanised Steel Roofing CEE C Purlin Roll Forming Production Line For Constructions:

6, Galvanised Steel Roofing CEE C Purlin Roll Forming Production Line Working Flow: